Scandlines operates ferries with high requirements for uptime, safety, and documentation. Their operations depend on critical spare parts and rotating components, many of which are regularly sent to external partners for service, repair, or calibration.

Over time, managing these assets became increasingly complex. Existing systems did not provide sufficient insight or traceability, making it difficult to maintain control over part location, service status, and documentation.

Standardized processes and full visibility give Scandlines better control of spare parts and service operations, reducing complexity and improving fleet-wide transparency.

Unclear processes around critical spare parts led to:

- Manual follow-ups and administrative overhead

- Inconsistent documentation

- Limited overview of parts in service or use

- Reduced transparency across daily operations

Scandlines needed a structured solution that supported daily operations without adding complexity.

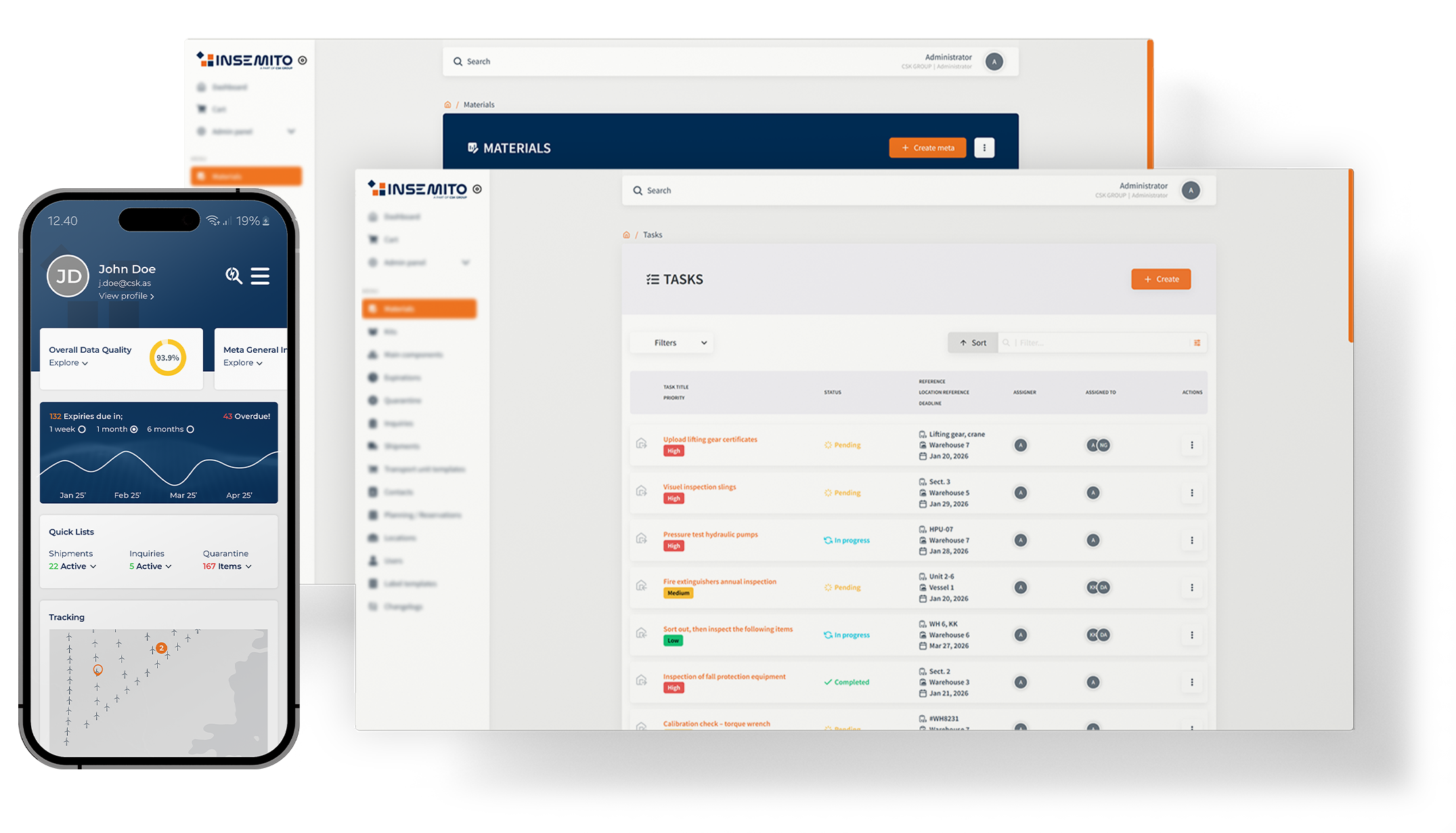

Insemito delivered a structured Task function within Insemito providing a centralized overview of all tasks related to critical spare parts.

Each task is linked to item and serial number level, ensuring correct handling of certificates, calibration records, service reports, and repair documentation. Internal teams and external service partners work in the same structured workflow, with clear task ownership and status tracking.

Empowering operational excellence across global industries.

The future of O&M — accessible. Anywhere.